Advantage:

This type of line offers three possibilities:

- Producing a solid product

- Producing a hollow product

- Producing a filled product (jelly, syrup, chocolate…powder, citric acid…)

A production line can be composed as follows:

- Extruder for the production of solid or a hollow rope filled with a powder or liquid

- Conveyor

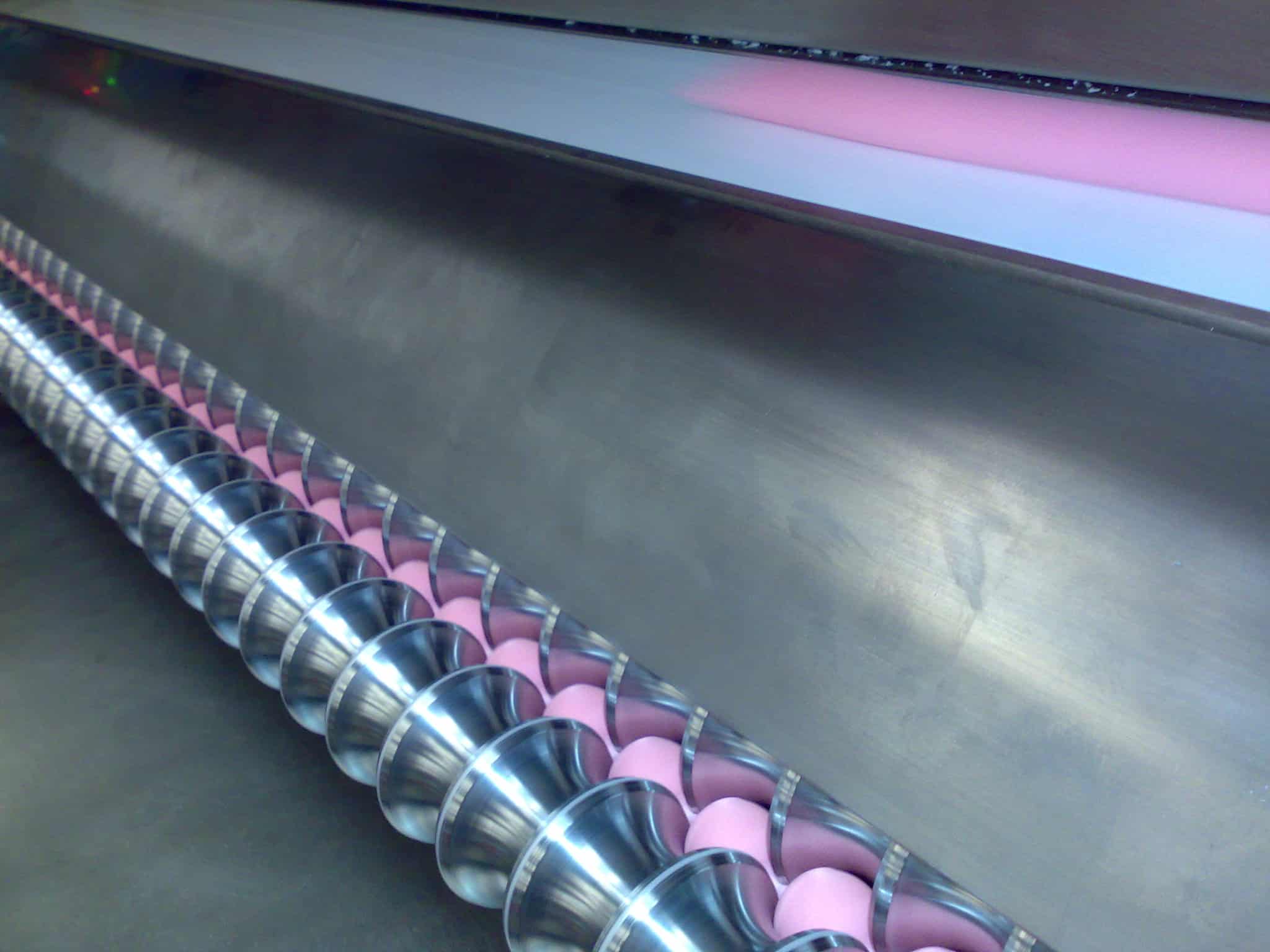

- Ball Former for the final shape of the products

- Cooling Table

In order to ensure smooth, high production our BF 1002 Ball Forming Machine works continuously.

Its flexibility allows you to produce different formats and / or diameters simultaneously.

Make Filled Products:

Three types of different fillings:

- Powder filling

- Liquid filling

- Semi-liquid filling

Example:

- Our Extruder can feed several Ball Formers BF 1002, each of which is equipped with another format.

- As the production parameters are memorized, format changes are quick.

- Products made on the Ball Former can be coated or directly wrapped.

- Maintenance is minimal and is easy access.

We have a test machine available for the development of new products, contact us !