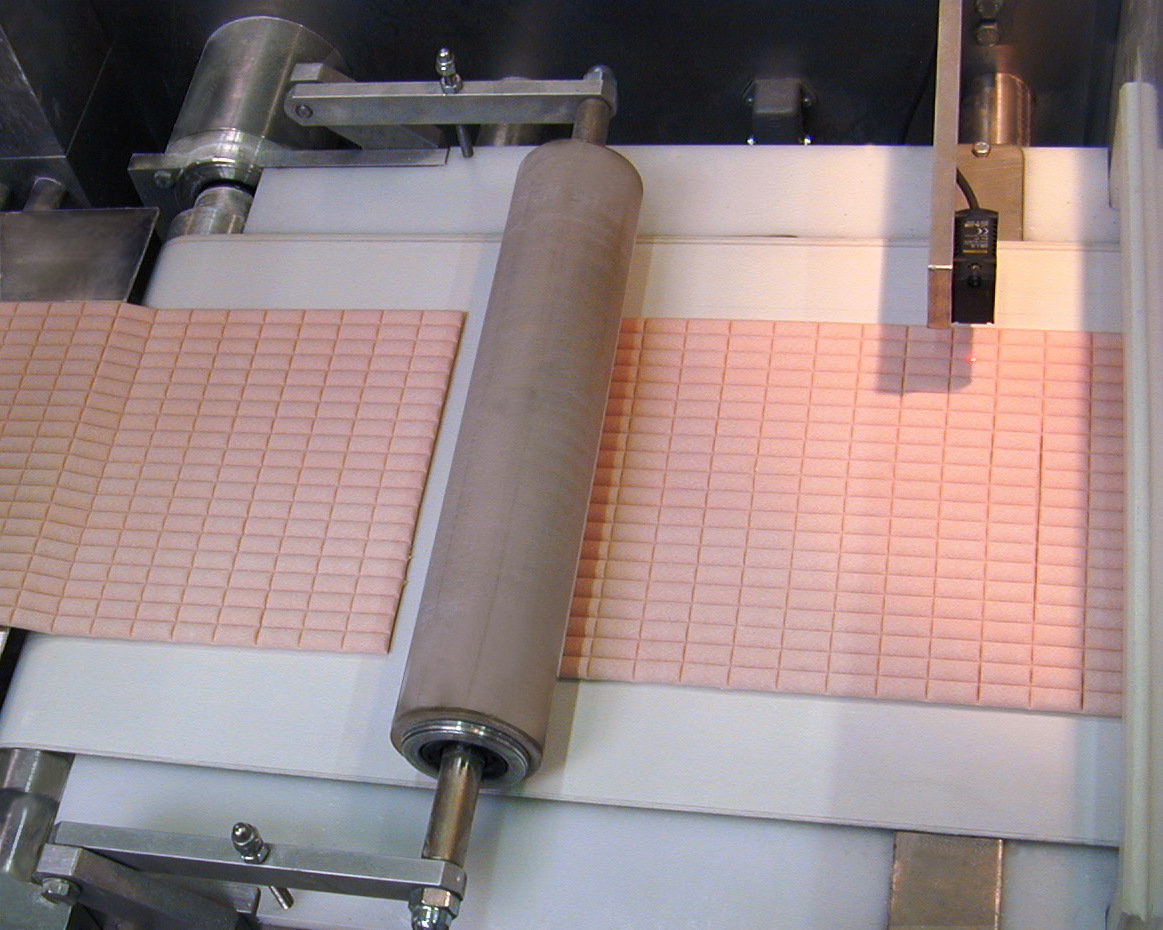

ROLLING & SCORING PRODUCTION LINES

A production line can be composed as follows:

Advantages of a Rolling & Scoring Line:

- The Rolling & Scoring Machine can be fed by a Co-Extruder to make two color products

- Low operator intervention -> format changes are quick & simple

- Upper and lower brushing system connected to a centralized vacuum system reduces dust emissions

- Powder recycling system

- Autonomous and modular powdering system, for a quick change from a sugar product to a sugarless one

- Metal detection and ejection system to evacuate contaminated products

- Tempering of rolling cylinders, for constant quality production

- Modular stations for simple and quick format changes

- Quality control system, verifying the exact dimensions and weight of each sheet made

- Tempering and Curing Tunnel

- Optional passage on a stainless steel cooling belt BR

- Stacking of the sheets made at output, either manual or entirely automated

- Breaking Drum, reducing the scored sheets into individual pieces

- Manual control system or via PLC with recipe and production parameter management

- ATEX execution available upon request

Different standard executions are available, in order to best respond to your production requirements.

Examples of finished products (chewing-gum in 1 or 2 colors):

- Pellets

- Sticks

- Tabs