Application/Product:

- Toffee, Caramel, Chewy Candy, Soft Chews -> 1 color & 1 flavor

Capacity:

- 200 kg/h and above (according to application)

- Several ropes (according to the product)

Construction:

- Lacquered / painted steel

- Stainless steel

Options:

- Powdering

- Ingredient metering units

- Cooling of screws

- CIP system…

Advantages:

- 1 Single Machine to: Cool, crystallize, mix-in ingredients and split the mass into several ropes.

The Intruder’s strength: 4 functions in 1 machine.

- Directly takes in the product mass from the cooker for efficient cooling, without other machinery

- Continuous graining or crystallization of the soft candy

- Incorporation of coloring, flavoring, citric acid… which transform a neutral product into a finished product

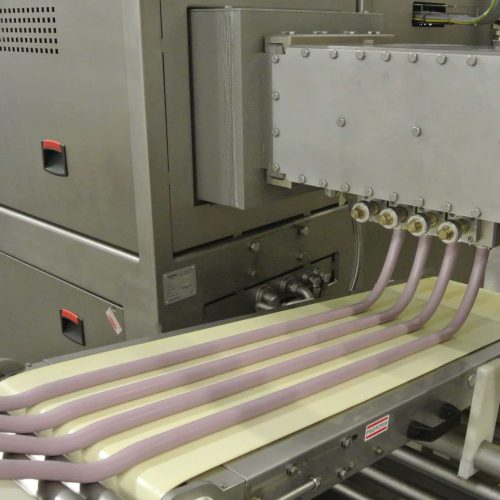

- At the Intruder output : splitting of the mass into several ropes, to continually feed downstream equipment.

Other Advantages of the Intruder:

- The machine is self-cleaning. This saves the time used for cleaning and also water.

- Production start and stop are simplified.

- In case of a power outage, it is possible to resume production without cleaning or other work.

- According to your production needs, the Intruder can form several ropes of different dimensions. Our Intruder is capable of feeding your downstream installations, running at different speeds

Option:

CIP system

Innovative Technology:

- The Intruder replaces a Cooling Drum or cooling belt, thus eliminating the difficulties of product sticking.

- The Intruder replaces a pulling machine or a z-blade mixer. It also eliminates the lumps that can be produced by these machines resulting in very regular, fine texture and product.

- The level of texture or degree of hardness can easily be adjusted to prevent any retraction of the candy or toffee mass after discharge.